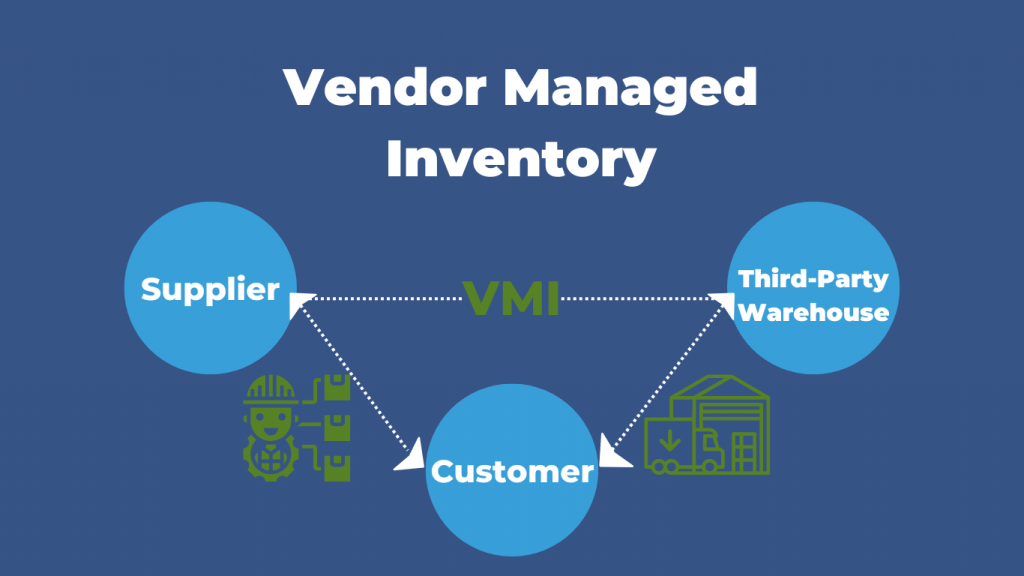

Vendor management inventory is an arrangement where the suppliers manage the inventory levels that have been pre-determined. In a nutshell, the supplier takes the decision on behalf of the retailer wherein supplier fills up the inventory continuously.

However it is important to effectively implement the vendor management inventory – VMI system to get desired results.

The tips for improving VMI

Establish clear communication: Effective and transparent communication channel is significant for the success of VMI. It is important to establish clear lines of communication with the suppliers and customers to make sure everyone is on the same page and that any issue or changes are communicated promptly.

Collect and analyze data: Collect and analyze accurate and reliable data to make sure the inventory levels are managed effectively. With the help of the data collected, one can easily track trends and make informed decisions about the inventory levels.

Develop a comprehensive VMI plan: It is important to develop a cutting-edge Vendor management inventory plan that clarifies goals, objectives, and responsibilities of all the parties involved. The plan includes performance metrics that can be used to evaluate the effectiveness of the method.

Trust and transparency: Building trust and transparency between supplier and customer is significant to the success of vendor management inventory. Both parties should willingly share the data and work collaboratively to make sure inventory levels are effectively managed.

Technology to automate process: It is important to use the state-of-the-art technology to automate the processes like data collection, inventory tracking and order processing. This can help minimize errors and improve the efficiency.

Monitor performance and make adjustments: Monitoring the performance of VMI system regularly and make changes accordingly. With the help of performance metric outlined in the VMI plan one can easily evaluate the effectiveness of the program and identify areas that need improvem.

Train the employees: It is equally important to make sure that the employees are trained for VMI and also they understand their roles and responsibilities. With this one can be rest assured that the program is implemented effectively and that everyone is working towards the same goals.

How to implement vendor management inventory?

1. It is very important to identify the key stakeholders that include supplier, customer, and other parties involved in the process.

2. Define the inventory levels and replenishment frequency for every product or SKUs, taking into account factors like lead times, demand patterns and safety stock needs.

3. Also, determine the method for data exchange between supplier and customer

4. Developing communication protocols will ensure both parties are aware of any changes or issues related to inventory levels, deliveries or orders.

5. Train personnel on the VMI including how to use data exchange methods, how to monitor inventory levels and how to respond to issues or changes in VMI relationships.

6. Establish performance metrics to monitor effectiveness of VMI relationship like inventory accuracy, order fulfillment times and customer satisfaction.

Wrap up

Vendor management inventory is a robust inventory management method that has proven to be successful across various sectors. It allows suppliers to manage their customer inventory levels thus fostering minimized inventory carrying costs, improved order fulfillment times and enhanced sales.